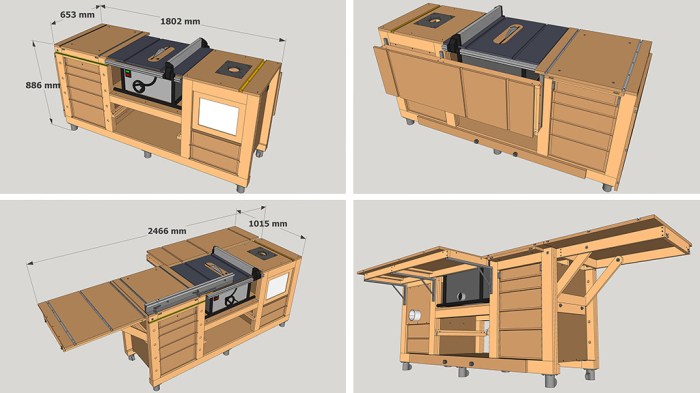

A DIY saw bench is a valuable addition to any workshop, offering versatility and functionality for a variety of woodworking tasks. From cutting lumber to shaping intricate pieces, a well-designed saw bench provides a stable and secure platform for precise work.

Whether you’re a seasoned woodworker or just starting out, building your own saw bench can be a rewarding and fulfilling project. By carefully considering the design, materials, and construction techniques, you can create a custom-built saw bench that meets your specific needs and enhances your woodworking experience.

Design Considerations for a DIY Saw Bench

A saw bench is a fundamental woodworking tool that provides a stable platform for cutting lumber accurately and safely. Building a saw bench yourself offers a chance to customize it to your specific needs and woodworking style. This section will explore key design considerations to help you build a saw bench that meets your requirements.

Essential Components of a Saw Bench

The essential components of a saw bench include the base, top, and supports.

* Base: The base provides the foundation for the saw bench, ensuring stability and strength. It should be robust enough to withstand the weight of the bench, the saw, and the workpiece.

* Top: The top is the working surface of the saw bench. It should be flat and smooth, providing a stable platform for cutting.

* Supports: Supports are crucial for providing rigidity and strength to the saw bench. They can be incorporated into the base or added as separate structures to support the top.

Materials for Construction

A wide range of materials can be used to build a saw bench. The choice depends on your budget, desired durability, and aesthetic preferences.

* Wood: Wood is a popular choice for saw bench construction due to its affordability, ease of working with, and aesthetic appeal. Softwoods like pine or fir are cost-effective, while hardwoods like oak or maple offer greater durability.

* Metal: Metal offers superior strength and durability compared to wood. Steel or aluminum can be used for the base, supports, and even the top.

* Combination: Combining wood and metal can create a saw bench with the best of both worlds. Wood can be used for the top and supports, while metal can be used for the base, offering strength and stability.

Design Styles and Layouts

Saw bench designs vary depending on the intended use and the space available.

* Simple and Compact: A simple and compact design can be ideal for smaller workshops or those with limited space. These benches typically have a basic frame and a small top.

* Large and Sturdy: A larger and sturdier design can be suitable for more demanding woodworking tasks and heavier saws. These benches often have a wider top and more robust construction.

* Modular: Modular designs allow for customization and expansion. Components can be added or rearranged to suit changing needs.

Building a DIY Saw Bench

A DIY saw bench is a valuable addition to any workshop, providing a stable and accurate platform for cutting wood. This guide will walk you through the process of building your own saw bench, step-by-step.

Materials and Tools

The first step is to gather the necessary materials and tools. The materials list may vary depending on your design and desired size. Here’s a general list:

- Wood: Choose a durable and stable wood like hardwood, plywood, or MDF for the main structure. Consider using a combination of materials for different parts.

- Fasteners: Use screws, bolts, and glue for secure and lasting assembly. Select the appropriate size and type based on the wood thickness and load-bearing requirements.

- Work surface: For the top, use a flat and smooth material such as plywood or a solid wood board. This is where you’ll be cutting your wood.

- Saw: The saw you plan to use will influence the design of the saw bench. Consider the size and type of saw you have.

- Clamps: Use clamps to hold the pieces together during assembly.

- Measuring tools: Accurate measurements are essential for a stable and functional saw bench. Use a tape measure, ruler, and square.

- Safety gear: Always wear safety glasses, ear protection, and a dust mask when working with wood.

Cutting the Components

With your materials gathered, it’s time to cut the components according to your chosen saw bench design.

- Use a circular saw, table saw, or miter saw to make accurate cuts.

- Double-check your measurements before making any cuts.

- For the main frame, cut the wood to the desired dimensions. The frame should be strong enough to support the weight of the saw and the workpiece.

- Cut the work surface to the desired size. It should be slightly larger than the saw blade to provide enough support.

- Cut any additional components like legs, bracing, or storage shelves.

Assembling the Frame

The next step is to assemble the frame.

- Use screws, bolts, or glue to join the pieces together.

- Make sure all joints are square and tight.

- Use clamps to hold the pieces together while you secure them with fasteners.

- If using glue, allow it to dry completely before proceeding.

Securing the Work Surface

Once the frame is assembled, you can attach the work surface.

- Align the work surface with the frame and secure it using screws or bolts.

- Make sure the work surface is level and flush with the frame.

Adding Additional Features

You can add additional features to your saw bench to make it more functional.

- Add a fence to guide your cuts.

- Include storage shelves for tools and materials.

- Mount a dust collection system to keep your workspace clean.

Finishing Touches

After the construction is complete, you can add finishing touches to your saw bench.

- Sand the surfaces smooth and apply a sealant or finish to protect the wood.

- Add a coat of paint or stain for a personalized look.

Essential Tools and Equipment

Building a DIY saw bench requires a range of tools, both power and hand tools, to ensure accuracy, precision, and safety during construction. The selection of tools depends on the specific design and materials used for the saw bench.

Power Tools, Diy saw bench

Power tools are essential for cutting, shaping, and assembling the saw bench. They significantly speed up the process and improve accuracy, but require proper handling and safety measures.

- Circular Saw: This versatile tool is used for cutting wood to size and shape. It features a rotating blade that cuts through wood with ease. When selecting a circular saw, consider factors such as blade size, power, and cutting depth. Examples include the DeWalt DWE575K and the Bosch GKS190.

- Jig Saw: A jig saw is used for cutting intricate curves and shapes in wood. It features a reciprocating blade that moves up and down, allowing for precise cuts. When choosing a jig saw, consider the blade stroke length, speed control, and blade change mechanism. Examples include the Ryobi PJS1818 and the Makita JV0100.

- Drill/Driver: A drill/driver is essential for drilling pilot holes and driving screws. It features a chuck that holds different drill bits and screwdriver tips. When selecting a drill/driver, consider factors such as power, torque, and speed control. Examples include the Milwaukee 2804-20 and the DeWalt DCD771C2.

- Router: A router is used for creating precise edges, grooves, and other intricate details in wood. It features a rotating bit that cuts into the wood. When selecting a router, consider factors such as power, speed control, and depth adjustment. Examples include the Bosch 1617EVSPK and the DeWalt DWP611PK.

- Belt Sander: A belt sander is used for sanding large surfaces and removing rough edges. It features a continuous belt that moves over the wood, removing material quickly and efficiently. When selecting a belt sander, consider factors such as belt size, power, and speed control. Examples include the Makita 9903 and the Bosch GSS230.

Hand Tools

Hand tools are essential for precise measurements, marking, and assembly. They provide finer control and are often used in conjunction with power tools.

- Tape Measure: A tape measure is used for measuring the length, width, and depth of wood. It features a retractable tape with markings in inches or centimeters.

- Speed Square: A speed square is a multi-purpose tool used for marking and cutting angles. It features a right angle and a 45-degree angle, allowing for accurate marking and cutting.

- Combination Square: A combination square is used for measuring and marking straight lines and angles. It features a ruler, a protractor, and a blade that can be adjusted to different angles.

- Level: A level is used to ensure that surfaces are horizontal or vertical. It features a vial with a bubble that indicates when the surface is level.

- Clamps: Clamps are used to hold wood pieces together while gluing or assembling. They come in various sizes and types, such as bar clamps, C-clamps, and spring clamps.

- Hammer: A hammer is used for driving nails and other fasteners. It features a head with a striking surface and a handle.

- Screwdriver: A screwdriver is used for driving screws. It features a handle and a tip that fits into the screw head.

- Chisel: A chisel is used for cutting and shaping wood. It features a sharp blade and a handle.

- Mallet: A mallet is used for striking chisels and other tools without damaging the wood. It features a rubber or wooden head and a handle.

Safety Precautions

Safety is paramount when working with power tools and hand tools. Always wear appropriate safety gear, such as safety glasses, hearing protection, and work gloves. Follow the manufacturer’s instructions for each tool and use the correct safety procedures.

- Always wear safety glasses: This protects your eyes from flying debris and dust.

- Use hearing protection: Power tools can generate loud noises, which can damage your hearing over time.

- Wear work gloves: Gloves protect your hands from splinters and cuts.

- Keep your work area clean and organized: This reduces the risk of tripping or falling.

- Never use a tool that is damaged or malfunctioning: This could lead to serious injury.

- Always unplug tools before making adjustments or changing blades: This prevents accidental starts.

- Be aware of your surroundings: Make sure there are no obstructions in your work area.

- Use a dust mask or respirator: This protects your lungs from sawdust and other airborne particles.

Customization and Personalization

The beauty of a DIY saw bench lies in its adaptability. You can tailor it to your specific needs and preferences, creating a workstation that enhances your woodworking experience. From unique features and storage solutions to aesthetic enhancements, there’s a world of customization possibilities waiting to be explored.

Incorporating Unique Features

Unique features can elevate your saw bench from a simple tool to a personalized workstation. Consider adding features that enhance functionality and efficiency.

- Integrated Dust Collection: A built-in dust collection system can significantly improve your workspace by minimizing dust and debris. You can design a system that connects to your shop vacuum or a dedicated dust collector.

- Outfeed Support: An outfeed table extending beyond the saw bench provides a stable surface for supporting long workpieces as they are cut, reducing the risk of kickback.

- Adjustable Fence: A precisely adjustable fence allows for accurate and repeatable cuts.

- Miter Gauge: A miter gauge simplifies cutting angles, enabling you to make precise miter joints.

Storage Solutions

Storage solutions are crucial for keeping your saw bench organized and your tools readily accessible.

- Built-in Shelves: Shelves can be incorporated into the design to store tools, supplies, and project materials.

- Drawer System: Drawers provide convenient storage for smaller tools and accessories.

- Pegboard: A pegboard can be used to hang tools, keeping them visible and organized.

- Tool Caddy: A tool caddy mounted to the bench can hold frequently used tools, keeping them within easy reach.

Aesthetic Enhancements

Beyond functionality, you can personalize your saw bench with aesthetic enhancements.

- Finishing Touches: Apply a stain or paint to give your saw bench a desired look and protect the wood.

- Hardware Selection: Choose high-quality hardware that complements the overall design and enhances durability.

- Customizable Design: Incorporate unique design elements, such as curves, angles, or decorative accents, to create a distinctive look.

Ergonomics and User Comfort

Ergonomics plays a crucial role in designing a comfortable and efficient saw bench.

- Work Surface Height: Adjust the work surface height to ensure a comfortable posture while cutting.

- Footrest: A footrest provides support and helps maintain proper posture.

- Lighting: Adequate lighting is essential for accurate cutting and reducing eye strain.

Conclusion

Building a DIY saw bench is a rewarding project that offers numerous benefits, from cost savings to personalized functionality. It empowers you to create a custom workspace tailored to your specific needs and preferences, enhancing your woodworking experience.

Benefits of a DIY Saw Bench

The advantages of constructing your own saw bench are multifaceted:

- Cost-Effectiveness: DIY saw benches can be significantly cheaper than commercially available options, allowing you to allocate your budget towards other essential tools and materials.

- Customization: You have complete control over the design, dimensions, and features of your saw bench, ensuring it perfectly suits your workspace and woodworking style.

- Improved Accuracy: A well-built saw bench provides a stable and precise platform for your saw, leading to more accurate cuts and improved woodworking results.

- Enhanced Work Efficiency: A dedicated saw bench streamlines your workflow by providing a designated area for cutting, reducing setup time and maximizing productivity.

- Increased Safety: A stable saw bench reduces the risk of accidents by providing a secure platform for your saw and materials.

With careful planning and attention to detail, building a DIY saw bench is a project that can greatly enhance your woodworking capabilities. The satisfaction of creating a functional and personalized tool for your workshop is unmatched. So, gather your tools, select your materials, and embark on your own DIY saw bench journey.

A DIY saw bench is a great project for any woodworker, providing a stable and adjustable platform for cutting. You can customize it to fit your specific needs, whether you’re working on intricate woodworking projects or just need a sturdy base for your saw. If you’re looking for inspiration for holiday decorations, check out these DIY outdoor Christmas decorations that will add a festive touch to your home.

Once you’ve finished your decorations, you can use your saw bench to create a custom frame for a holiday wreath or other festive projects.